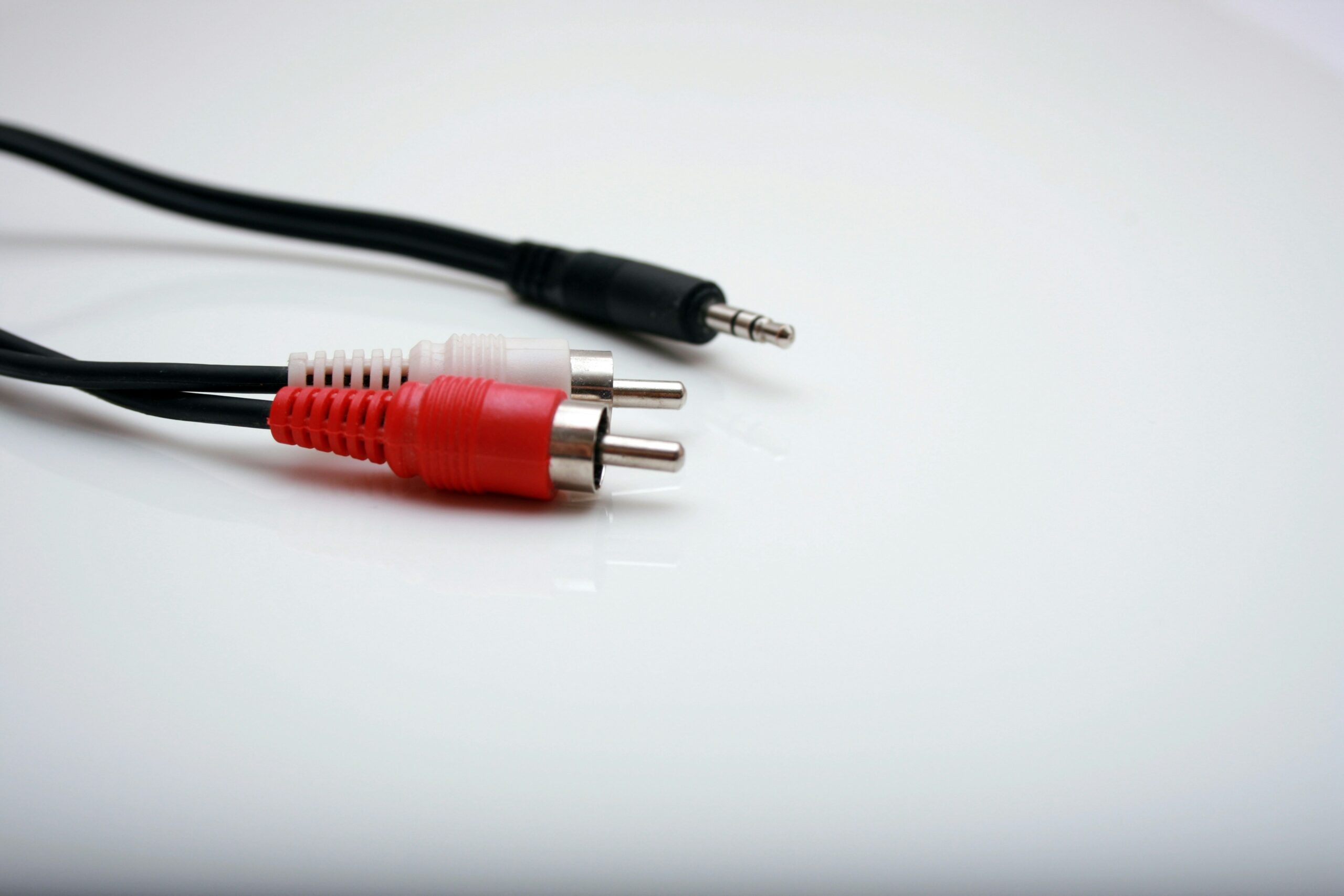

Photo by <a href="https://unsplash.com/@0asa" rel="nofollow">Vincent Botta</a> on <a href="https://unsplash.com/?utm_source=hostinger&utm_medium=referral" rel="nofollow">Unsplash</a>

Introduction to the 39850-0500 Connector

The 39850-0500 connector represents a crucial component within the realm of electrical connectivity. This connector has been designed to facilitate efficient and reliable connections in various applications, thereby ensuring the seamless functioning of numerous devices. Its robust construction is tailored to meet specific requirements across different industries, making it a favored choice among engineers and manufacturers alike.

The primary purpose of the 39850-0500 connector is to enable the transfer of electrical signals with minimal loss and interference. Given the increasing complexity of modern electronic systems, connectors like the 39850-0500 are imperative for achieving optimal performance. This connector is generally utilized in demanding environments, where durability and reliability are of utmost importance. Its versatility allows it to be employed in applications ranging from automotive systems to industrial machinery, hence underscoring its significance.

In terms of construction, the 39850-0500 connector is engineered with high-quality materials that ensure exceptional performance and longevity. Its design typically includes features such as secure locking mechanisms and weatherproof seals, further enhancing its suitability for various settings. The ability to withstand harsh conditions while maintaining electrical integrity has made this connector a vital element in the design of contemporary electronic layouts.

Moreover, understanding the specifications of the 39850-0500 connector is essential for anyone involved in cable assembly, circuit design, or electronic manufacturing. Familiarity with its characteristics enables professionals to make informed decisions regarding its application in various projects, thereby optimizing functionality and ensuring safety. As we delve deeper into the specifications and applications of the 39850-0500 connector, it becomes clear that its role extends far beyond a simple connection point, highlighting its importance in the modern technological landscape.

Specifications of the 39850-0500 Connector

The 39850-0500 connector is engineered to meet specific needs within various electronic applications. Its dimensions are critical for ensuring compatibility with other electronic components. Typically, the 39850-0500 connector measures approximately 20mm in length, 12mm in width, and has a height of around 6mm. It is designed for use in compact spaces, necessitating precise dimensional specifications to enable efficient integration into circuit boards and other electronic assemblies.

Material composition plays a vital role in the functionality and durability of the 39850-0500 connector. The housing is primarily constructed of high-grade thermoplastic, which provides excellent thermal stability and resistance to various environmental factors. The contact pins are made from copper alloy, which enhances conductivity while maintaining resistance to corrosion. This combination ensures that the connector operates efficiently under varying environmental conditions, contributing to its longevity.

Electrical properties are essential in evaluating the efficacy of the 39850-0500 connector. The connector is rated for a maximum current of 10 amps and operates at a voltage range of 30V to 50V. This makes it suitable for low to medium power applications, ensuring a reliable connection in both signal and power transmission. The mechanical properties further enhance its usability; the connector exhibits a mating cycle life of over 500 insertions, underscoring its robustness in repeated applications.

Moreover, the 39850-0500 connector adheres to various compliance standards, including RoHS and UL certifications. These certifications ensure that the connector complies with environmental regulations and safety standards, making it a reliable choice for manufacturers and engineers alike. Detailed diagrams accompanying these specifications will illustrate the connector’s design features and confirm its applications across multiple industries.

Design Features of the 39850-0500 Connector

The 39850-0500 connector boasts a variety of design features that ensure reliable performance in demanding applications. A key aspect of its design is the innovative locking mechanism which secures the connection firmly, preventing accidental disconnections. This feature is particularly vital in environments where vibrations or movements are common, as it provides enhanced stability and dependability.

Another important element is the contact arrangement of the 39850-0500 connector. It typically employs a multi-contact configuration, which helps in distributing electrical loads evenly across the contacts. This design mitigates issues such as overheating and ensures that the connector maintains a consistent performance level, even under varying operational conditions. Furthermore, the arrangement allows for a higher degree of reliability since multiple contacts are able to conduct electricity together, thus improving overall efficiency.

Environmental sealing is also a critical feature of the 39850-0500 connector. It is often designed with gaskets and seals to prevent moisture, dust, and other contaminants from penetrating the connector housing. Such sealing mechanisms play an essential role in preserving the integrity and functionality of the connector during prolonged exposure to harsh conditions, including high humidity and extreme temperatures. This is especially relevant in aerospace and automotive applications where protecting internal components from the elements is paramount.

Durability is another hallmark of the 39850-0500 connector’s design. Constructed using high-quality materials, it offers exceptional resistance to wear and corrosion. This resilience contributes to a long service life, making it a cost-effective solution for manufacturers seeking reliable connectors for their products. With its combination of locking features, efficient contact arrangement, sealing capabilities, and durable construction, the 39850-0500 connector emerges as a robust choice for various industrial applications.

Common Applications of the 39850-0500 Connector

The 39850-0500 connector is an integral component in various industries, known for its reliability and versatility. One of the primary sectors utilizing this connector is the automotive industry. The automotive applications of the 39850-0500 connector include use in a variety of electronic systems such as engine control units (ECUs), powertrain modules, and advanced driver assistance systems (ADAS). Its ability to withstand harsh environmental conditions and ensure secure connections makes it a preferred choice for automotive manufacturers aiming for both performance and safety.

In the telecommunications sector, the 39850-0500 connector is utilized in equipment that supports high-speed data transmission. This connector’s design facilitates reliable connections in devices like routers, switches, and broadband modems, thereby enhancing data integrity and minimizing signal loss. Its compact size does not compromise on performance, enabling the seamless integration of advanced technologies in communication networks.

The aerospace industry also benefits from the unique qualities of the 39850-0500 connector. Within this sector, it is employed in avionics systems, where it must endure extreme temperature variations and high levels of vibration. Its robust design ensures the safety and efficiency of critical aerospace applications, supporting everything from navigation systems to flight control interfaces.

Furthermore, the industrial automation field takes advantage of the 39850-0500 connector in machinery and robotic systems. These connectors facilitate communication between control systems, sensors, and actuators, ensuring smooth operations in manufacturing environments. The durability and reliability of the connector in industrial settings contribute significantly to minimizing downtime, which is a critical aspect of efficient production processes.

In conclusion, the 39850-0500 connector is favored across multiple industries – automotive, telecommunications, aerospace, and industrial automation – due to its reliability, performance, and adaptability to various applications, making it an essential component in contemporary technology systems.

Benefits of Using the 39850-0500 Connector

The 39850-0500 connector offers several advantages that make it an outstanding choice for various applications in today’s technology landscape. One of the primary benefits is its remarkable reliability. This connector is designed to ensure a stable and secure connection, which is critical in environments where performance and safety are paramount. The robust construction and high-quality materials used in the 39850-0500 guarantee it can withstand mechanical stresses and environmental factors, resulting in minimal downtime and enhanced operational efficiency.

Another notable benefit of the 39850-0500 connector is its ease of installation. The connector’s user-friendly design allows for quick connections, enabling technicians to complete installations with precision and speed. This feature is particularly advantageous in projects with tight deadlines, as it reduces labor costs and the overall time required for setup. Additionally, its compatibility with various systems simplifies integration, making it a versatile choice for diverse applications.

Cost-effectiveness is yet another compelling reason to choose the 39850-0500 connector. While the initial investment in high-quality connectors might seem higher than cheaper alternatives, the longevity and reliability of the 39850-0500 lead to reduced maintenance costs and fewer replacement needs over time. Businesses can benefit from decreased operational costs and increased return on investment, making this connector an economically sound choice for long-term projects.

Lastly, users experience minimal maintenance requirements with the 39850-0500 connector. Its resilient design reduces the likelihood of wear and tear, allowing for consistent performance without frequent inspections or replacements. This blend of reliability, simple installation, economic viability, and low maintenance makes the 39850-0500 connector a superior option compared to other connectors on the market.

Installation Guidelines for the 39850-0500 Connector

The installation of the 39850-0500 connector is a crucial process that requires adherence to specific guidelines to ensure functionality and safety. Before commencing the installation, it is essential to gather the necessary tools, which typically include wire strippers, crimping tools, a multimeter, and a heat gun, depending on the insulation requirements. Additionally, safety gear such as gloves and goggles should be worn to protect against potential hazards.

Begin the installation by preparing the wires for connection. Strip the ends of the wires to expose a sufficient amount of conductor, generally about one centimeter. It is paramount to maintain cleanliness during this process; any dust or moisture can compromise the connection. Next, insert the exposed wire into the connector and utilize the crimping tool to secure it firmly. Ensure that the crimp is done evenly, as an improperly crimped connector can lead to intermittent connections or failure.

Once the wires are securely attached, it is advisable to test the connection using a multimeter. This step is crucial as it helps to detect any possible faults before further assembly. Verify that the resistance is low and that there is continuity across the connections. If applicable, heat shrink tubing can be applied over the connections to provide extra protection against environmental factors.

While installing the 39850-0500 connector, be mindful of common pitfalls. Avoid excessive force when crimping, as it can damage the connectors or wires. It is also important to ensure that the connectors are not subjected to any undue strain during use, as this can lead to cable fatigue. Following these guidelines will not only help in achieving a successful installation but will also promote the longevity and reliability of the electrical connections.

Troubleshooting and Maintenance of the 39850-0500 Connector

The 39850-0500 connector plays a pivotal role in numerous applications, making it essential to address potential issues that users may encounter over time. One of the most common problems is poor connectivity, often attributed to dirt or corrosion on the connector pins. Users should regularly inspect the connectors for any signs of buildup, as this can hinder performance. Cleaning the pins with isopropyl alcohol and a soft cloth or brush is a recommended practice to ensure a clear connection.

Another prevalent issue is physical damage to the connector itself. Cracks, bends, or frayed wiring can compromise the integrity of the 39850-0500 connector. In such cases, a thorough visual inspection should be conducted. Users should handle the connectors with care during installation and removal to minimize the risk of physical damage. If any damage is identified, replacing the affected connector is crucial to maintaining reliable performance.

Wiring issues can also lead to malfunctioning connectors. Users must verify that all connections are secure and that wires are correctly routed to avoid accidental disconnections. Conducting regular tests with a multimeter can assist in identifying any short circuits or abnormalities in the wiring, ensuring that the connector operates effectively.

In terms of maintenance, proactive measures can significantly extend the lifespan of the 39850-0500 connector. Regularly scheduled inspections, ideally bi-annually, can help to ensure that any wear or underlying issues are identified early on. Additionally, utilizing protective covers when the connection is not in use can prevent dust and debris accumulation, thereby enhancing durability. It is advisable to maintain an environment with controlled humidity and temperature to minimize the potential for deterioration.

By following these troubleshooting techniques and maintenance tips, users can enhance the reliability and longevity of the 39850-0500 connector, ensuring optimal performance in their applications.

Future Trends in Connector Technology

The world of connector technology is undergoing significant transformations, driven by the constant demand for enhanced performance and versatility. One of the key trends is miniaturization, where manufacturers are designing connectors to be smaller yet more efficient. This shift is largely influenced by the miniaturization of electronic devices, including smartphones, tablets, and wearables, where space is limited. The 39850-0500 connector is no exception; as the need for compact connectivity solutions increases, designs that accommodate high-density applications will likely emerge.

In addition to miniaturization, there is a growing trend towards increased connectivity across various platforms. With the advent of the Internet of Things (IoT), devices require connectors that can not only allow for charging and data transfer but also facilitate robust communication between multiple devices. This trend is propelling the development of connectors that offer higher data transfer rates, greater bandwidth, and improved signal integrity. The 39850-0500 could potentially evolve to integrate these requirements, becoming a pivotal component in IoT architectures.

Moreover, the integration of smart technology into connectors is reshaping the landscape of connectivity. Smart connectors equipped with sensors, diagnostics, and data monitoring capabilities are becoming increasingly popular. These advanced connectors can provide real-time information regarding performance and can be programmed to optimize connection quality. The incorporation of such intelligent features can enhance the functionality of the 39850-0500 connector and improve user experience across various applications.

As we look towards the future, it is clear that connector technology will continue to advance, aligning with the trends of miniaturization, increased connectivity, and smart technology integration. Manufacturers will need to adapt to these changes, ensuring that connectors like the 39850-0500 meet the increasingly sophisticated demands of the market.

Conclusion and Final Thoughts

In summary, the 39850-0500 connector emerges as a pivotal component in the landscape of modern electrical connections. Its robust design and reliable performance make it an essential choice for a wide array of applications, from automotive to industrial settings. As technology continues to evolve, the importance of such high-quality connectors becomes increasingly pronounced, ensuring seamless communication and power distribution in various electronic systems.

Notably, the 39850-0500 connector is engineered to meet specified electrical and mechanical standards, thereby fostering not only safety but also efficiency in operations. Its specifications and compatibility with numerous devices suggest it can play a significant role in both current and emerging technologies. This adaptability indicates a potential for further innovation in the realm of connector design, as manufacturers explore ways to enhance functionality without compromising performance.

Moreover, as industries lean towards automation and smart technologies, connectors like the 39850-0500 are critical for maintaining sustainability and reliability. The demand for connectors that support high-speed data transmission and robust power delivery systems underscores the ongoing relevance of the 39850-0500 in modern applications. Developers and engineers are urged to consider the implications of such connectors in their designs, especially as opportunities for innovation evolve.

Ultimately, the 39850-0500 connector serves as a testament to the intricate interplay between technology and utility. As research and development initiatives continue to expand the potential of connector technology, it becomes increasingly vital for professionals in the field to remain informed about these advancements. By exploring the applications and further capabilities of the 39850-0500 connector, individuals and organizations can stay ahead in a rapidly changing technological landscape.